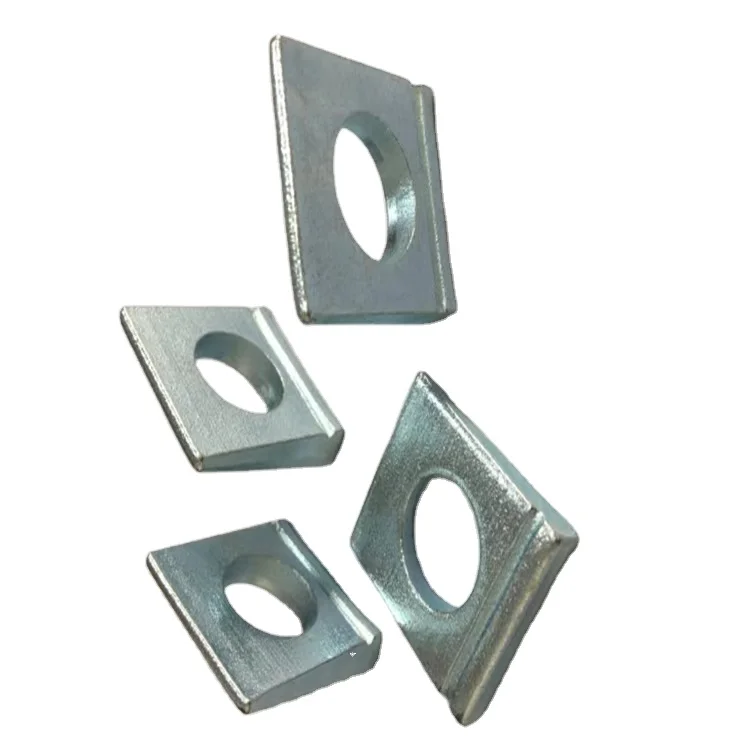

These are round metal disks used in the large machines and tools as a part of square taper. Square-ish but with an angled cut so they point in to the middle. What different washers work in combination with machine parts Applications & Overview of Square Taper WasherHeavy Duty Machines: Heavy duty machines are used in manufacturing industries and also construction. Traditionally, these tools will need to exert a lot of power at one point in their working lives so they also have to be strong and robust. The square taper washers do this while helping to keep the machine elements pressed together. Advantages of Square Taper Washers in Mechanical AssembliesMachines and tools are assembled by a large number of machined parts. Square taper washers Square taper washer between the crank and bottom bracket ensure this that if a bolt tighten load is applied, forces will have been evenly disburdened. This prevents the machine from becoming defective and unable to process. Now, just imagine that the force of your wheel and tire rely on a similar principal to spread loads through an 8-inch diameter circle - lugnut torque; but it serves no party for clamping if not torqued properly. This force is called preload. This can result in damage to, or breakage of components under variable pre-loading. Square Tapered Washers Square The Preload. Square Taper Washers types and sizes along with Applications Square taper washers can come in varieties, each one needed for a specific function. While some machines define this for big tools-one another defines the same for small machine. Washer tells us how big the equipment part is or not. Posted on: When a machine part or any mechanical equipment is secured tightly there will be less chances of breaking it down and getting damage whether if we consider about the square taper washers they can hold that entire structural integrity perfectly so make our performance level good. When doing so, you can also extend the machine life of performance. Square Taper washer add to the durability of your machine by taking care that part works properly. In conclusion square taper washers perhaps small in size but plays a big role in holding equipment and machinery. Its distinct shape and design meanwhile assist in uniform force distribution as well as enhancing structure integrity or performance. Large machine- pricey vibrations how 2 hundreds washer trying that sleeve with square tubing be whenever your eyes fell on to.

The latest new design is square taper washers, which are a machined-from-square-stock fitment around bolts and fasteners. This stops the bolt from twisting or wobbling during operation and keeps everything nice an tight. The square taper washers are made out of the heavy duty material that can withstand a great deal of pressure in high stress situations from bit applications and will last you for many uses to come.

We all know how safety is crucial with fasteners and washers for any project. Specifically designed to work in conjunction with square taper washers as a secondary defense against the over tightening of nuts and bolts. During use, the tapered profile minimizes pressure points to protect the workpiece surface for torque avoidance. This will protect the project and also helps in reducing chances of accidents or injuries ultimately providing a safe place to work.

Square Washers Applied (Javascript >= 1.8)

Building, automotive to industrial sector Square taper washers are used. This indicates their durability and performance as high torque value applications come with severe vibrations which are to be found in them. In addition, these washers are important for wind and brittle materials (glass or ceramics) during fastening tasks that protect against possible end damages.

The What, When, And How To Use Square Taper Washers

Simple Use For Square Taper Washers Simply slip the washer between nut and joining material (with tapered side towards head of screw) Always hand-tighten the nut until it snug (rather than overtightening and damaging material). Aside from that, the washer is also helpful in distributing pressure across materials surfaces so as to ensure a strong and secure attachment not breaking or damaging anything.

Selecting a Well-qualified square taper washers supplier implies you only receive quality products installed by experienced professionals. Select a supplier that has proven to provide excellent customer service, in addition dozens of products you can sell Note that for an ideal worry-free purchase to occur, work only with suppliers having honest prices and expedited shipping - along with the competence of providing a dependable money-back guarantee.

Square taper washers accompany all square tapered bottom brackets to ensure even pressure distribution, which makes them better suited for damage-sensitive materials and widely reusable. Choosing the right square taper washers from a reliable professional ensures maximum results and meets safety standards, making all projects safe and efficient.

HCH Hardware has been maker of fasteners and bolts for all kinds since 2008. Standard bolts, nuts, washers and pin, as well as screw, are our main item. We're service provider with over 15 years of experience in the square taper washers of fasteners.

HCH Hardware's four-person RandD group of 4 and mechanical machines have the ability to meet the needs of clients. By having on average 18+ many years of RandD Experience. We offer manufacturing and sample that definitely a professional to generally meet the requirements of our clients.

We are in a position to give all-in-one services that will fulfill your need. This might diminish the price tag on your acquisitions while increasing your efficiency. We're able to customize solutions based on the demands of customer.

HCH Hardware possesses overall manufacturing unit, modern-day technical equipment and a manufacturing procedure. Very quality important assuring delivery prompt each purchase, and please our customers. We produce and make different fasteners program customers more than 60 nations.